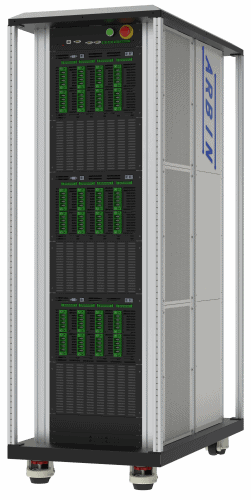

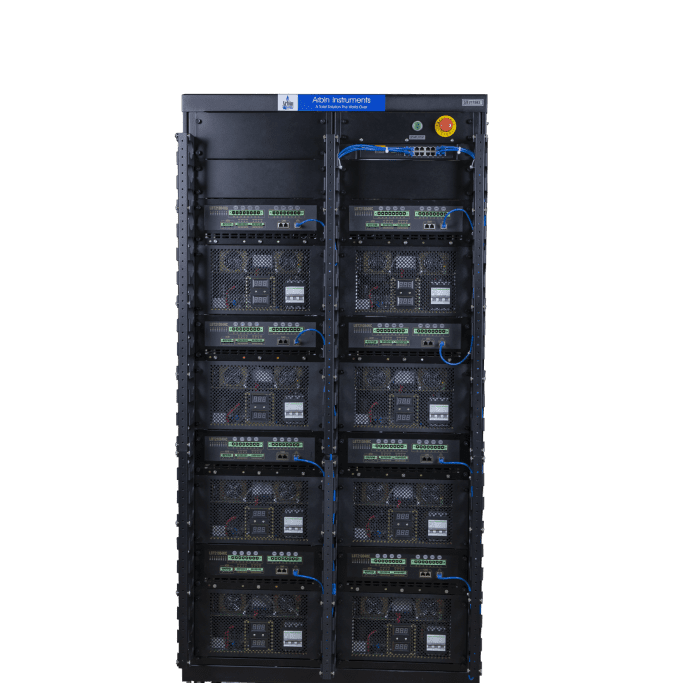

Regenerative Battery Test Series for Cells (RBT-Cell)

| Channel Voltage | 6V, 10V, and 20V Models |

| Channel Current | ±100A or ±400A per channel, Up to 1,600A |

| Channel Quantity | Up to 64 |

Arbin's RBT-Cell Battery Test Series is designed to meet the growing demand for regenerative battery testing. It offers high-current, cell-level test channels that use Arbin's regenerative technology for reliable and efficient testing and validation.

As the demand for energy storage solutions grows, so does the need for regenerative technology that not only accurately tests and characterizes batteries, but also contributes to a sustainable future.

Arbin’s Regenerative Battery Testing (RBT-Cell) series combines high-precision measurement and regenerative technology to reduce the overall energy cost of your testbed. This innovative technology enables researchers to generate reliable and repeatable data without compromising on results in the pursuit of energy efficiency.

Flexible Configurations

| Voltage Range Options | Current Ranges |

|---|---|

| 0 to 6V | 100A/25A or 400A/50A |

| 2 to 10V | 100/25A or 400A/50A |

| 2 to 20V | 100A/25A or 400A/50A |

Key Features

- Channel Density: 4 or 16 channels per module, capable of operating independently at ±100A or ± 400A per channel, or used in parallel to achieve current up to ±1,600A.

- Minimize Floor Space with up to 64 channels per rack in a compact footprint.

- Fully parallelable so any number of channels on the 16-channel module can be connected to increase the current-handling capability.

- Reduce Energy Consumption and HVAC load by utilizing efficient regenerative circuitry to return up to 85% of discharge energy back to the grid.

- Reduce Energy Consumption: Efficient regenerative circuitry can return up to 85% of discharge energy back to the system and/or grid.

RBT-Cell Specifications

| Hardware Specifications | |

|---|---|

| Channels per module | 4 or 16 |

| Number of Channels | Up to 64 |

| Voltage Range | 6V, 10V, or 20V |

| Current per channel | ±400A /channel (4CH), ±100A/channel (16CH) |

| Channel Parallel | Up to 16 Channels |

| Current Ranges | 2 |

| Rise Time | <1ms for 4CH module <2ms for 16CH module |

| Regenerative Efficiency | Up to 85% |

| Measurement Specifications | |

|---|---|

| Measurement Accuracy | 0.02% FSR |

| Measurement Precision | 0.01% FSR |

| Measurement Resolution | 24 Bit |

| Measurement Refresh Interval | 2ms for 4CH module, 8ms for 16CH module |

| Time Resolution | 100μs |

| Chassis Specifications | |

|---|---|

| Cooling | Air |

| Input Power | 340V - 520V |

| Chassis Size | Width: 25" / 635mm Depth: 45" / 1143mm Height: 72" / 1829mm |

Application Focus

- Facility integration to interface with temperature chambers, test facilities, or other third-party systems.

- Precision: Each channel provides multiple current ranges with industry-leading 24-bit resolution.

- Data Sampling and Logging: Powerful embedded controllers provide ultra-fast data sampling and logging.

- Comprehensive safety features for lithium-ion battery testing.

- Dynamic data acquisition based on changes in time, voltage, and current to capture more data when needed and maintain efficient file sizes.

- Simulation of Real World Test Profiles.

- dQdV & Coulombic Efficiency.

- Cell-level Quality Control & Grading.

Powerful Software Integration

- Create and manage test schedules, monitor real-time testing, and analyze results.

- Integration with third-party hardware and automation software.

- Suitable for both laboratory and production environments.

- Local and remote control of test channels.

- Test data securely stored in a range of robust database formats including MS SQL, Post GreSQL, Access, or utilize Apache Kafka for additional flexibility.

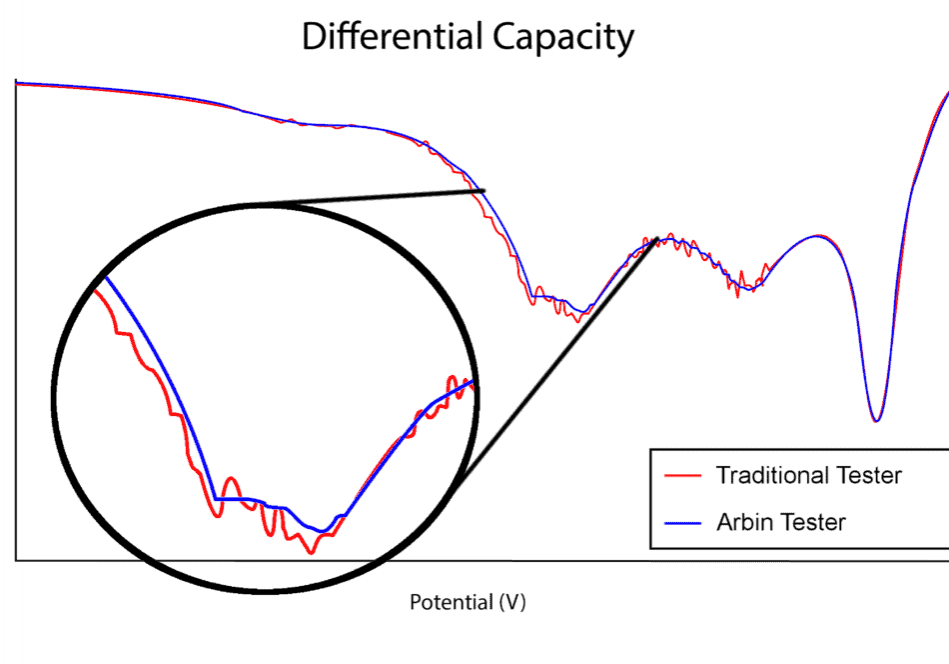

Importance of Precision

This plot illustrates the difference between an Arbin battery tester and another leading manufacturer. The first of the two distinct dips in the plot may have been missed using inferior test equipment. While many companies try to sell the same legacy equipment for over a decade, Arbin has been hard at work improving our designs to meet future industry demands. We learned a lot during our three year ARPA-E project to develop high-current high-precision testers, and have implemented this new technology in our LBT, RBT-Cell, and HPS test equipment series. The HPS ultra-high precision systems represent our premium product, but LBT is superior to other standard testers on the market.

Measurement precision is more critical for long‐term battery testing and long‐term battery projections than control accuracy alone. Most other battery testing systems do not correctly specify their precision and/or have relatively poor precision, which hinder the conclusions drawn from results data. Important trends and electrochemical indicators may remain unnoticed; lost in the measurement noise as illustrated at right.

What Affects Test Equipment Precision

Resolution of DAC

Resolution of ADC

Non-linearity of calibration

Short-term drift (temperature)

Long-term drift (material characteristics)

Arbin Test Equipment Improvements

Higher Resolution

Improved Software Algorithms

New Methods of Thermal Management

New Patented Shunt Design

New Method of Time Keeping

New Materials

Auxilaries and Optional Accessories Available to Enhance Testing

CANBus

Arbin offers CANBus interface(s) to allow real-time external control of the Arbin tester using CAN protocol. This feature allows for battery module/pack communication with a BMS (battery management system) or for cell testing where the client needs external control via CAN.

MTCI

The Temperature Chamber Interface (MTCI) allows the Arbin system to communicate with an approved third-party temperature/environment chamber. Arbin’s software can turn the chamber on/off and adjust the temperature during the test.

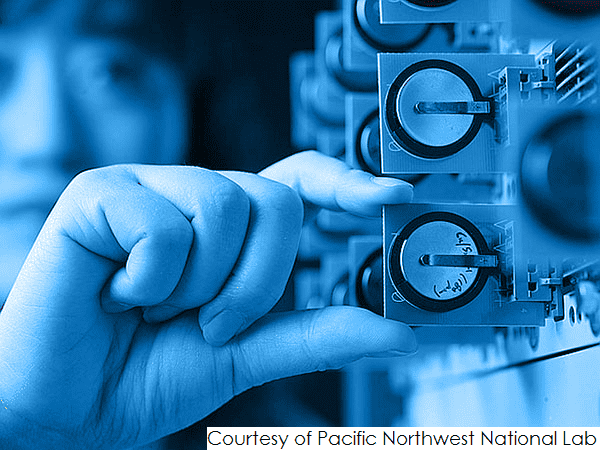

Battery Racks & Holders

A variety of racks and battery holder are available for all cell types for an organized test environment.

Arbin offers thermocouple and thermistor sensor types to measure and record temperature during testing. They function independently so the user may flexibly assign them in any configuration with the main charge/discharge test channels. All data is automatically synchronized with the cell charge/discharge test data. Available sensor types include:

- K-Type Thermocouples

- T-Type Thermocouples

- PT100 Thermistor (NOTE: PT100 thermistor inputs are compatible with Arbin MZTC Multi-Chamber.)

- 10kOhm Thermistor

Arbin offers an optional AutoCal module which can be used to re-calibrate the system when needed. All Arbin test equipment include a calibration interface as standard that can use an external meter to check or perform re-calibration. The AutoCal module is used to automate this process and will function without the need for an external meter.

NOTE: Arbin recommends equipment calibration is checked annually and re-calibrated as-needed.

AutoCal modules are available rated up to 200A, and High precision shunts are also available to use up to 600A.

Contact Us Today for a Quote

Complete our contact form to request a quote or learn how battery test equipment from Arbin Instruments can meet your testing requirements.